Manufacturing

Product and Quality Assurance Management through the product life cycle. Armorit provides project management, quality and logistics support services to deliver components and sub assemblies for integration into higher level systems.

Assembly

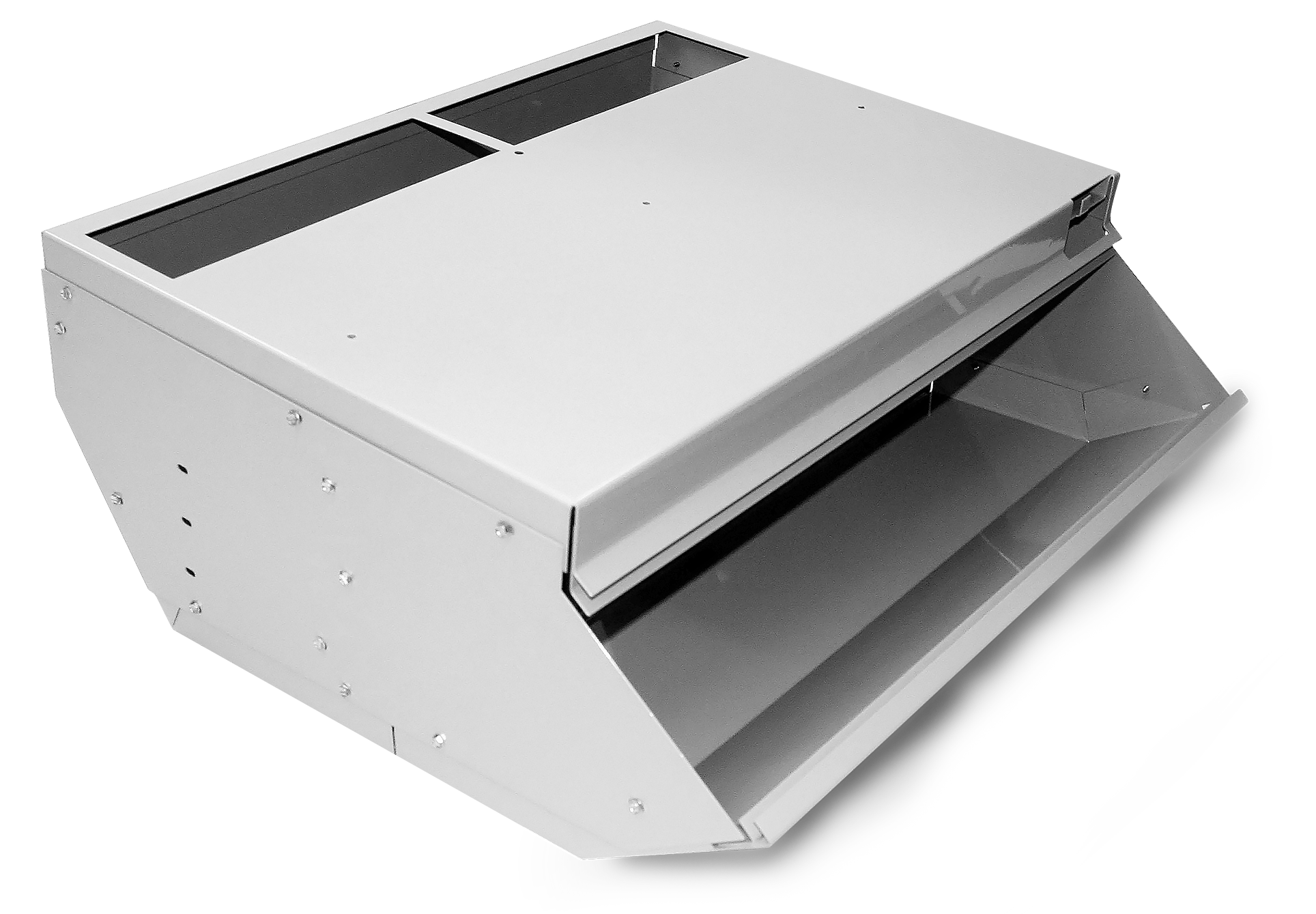

Armorit provides low to medium volume assembly for systems, sub-systems or components; providing finished goods or sub-assemblies to our customers. In addition, Armorit also uses custom assemblies and prototypes to support its product development activities.We Specialize In:

- Specialty Vehicle Sub-Systems

- Personal Protective Devices

- Mechanical Systems and Enclosures

- Cables and Wiring Harnesses

- Transportation Systems

- Custom Armor Applications

Commodity Areas

Armorit offers a extensive supplier base that enables us to deliver a wide range of products to meet our customer's needs. Our supplier base enhances our ability to generate rapid quote response, maintain competitive pricing and expand the types of commodities we can offer.Commodity Delivery Capabilities:

- Injection Molding

- Plastics

- Composites

- Sheet metal

- Weldments

- Castings

- Machined Parts

- Cables and Harnesses

Project Management

Armorit project management focuses on supporting our customers in a structured approach and executing the tasks necessary to achieve their business objectives. The prime directive of project management is to be on time, meet quality objectives and control the project within the budget. These activities form the classic time, quality and cost triangle.Project management is composed of several different types of activities and are assessed continually throughout the project life cycle

- Planning the work or objectives

- Analysis and design of objectives

- Assessing and mitigating risk

- Estimating resources

- Allocation of resources

- Organizing the work

- Aquiring human and material resources

- Assigning tasks

- Directing activities

- Controlling project execution

- Tracking and reporting progress

- Analyzing the results based on the facts achieved

Production Planning

Armorit production planning lays the ground work for meeting our customer's demands for a successful production life cycle. This organized approach is aimed at supporting the product development and manufacturing activities, with a goal of optimizing the costs and resources while maximizing profits.- Production plans and planning

- Special implementation task identification and action tracking

- Milestone scheduling

- Performance requirement designation

- Quality system implementation

- Product and process control plan

- Subcontract partner agreements

- Subcontract schedule commitments

- Long lead mitigation plan

- Special tooling plan

- Production tooling plan

- Engineering change methodology and approval

- End-of-life strategy

Legacy Modernization

To remain competitive in the market place it is sometimes necessary and cost effective to upgrade existing products, expand capacity or replace current suppliers.Armorit has the ability to:

- Replace a marginal supplier or one that is no longer in business

- Expand current capacity

Armorit can assist by providing design iterations to improve:

- Ease of assembly

- Manufacturability

- Quality

- Reliability

- Cost

Armorit offers a suite of services that are tailored to this effort:

- Reverse engineering

- Reengineering

- Transfer to production

- Portable CMM capabilities

- Dimensional, structural, vibration and thermal analysis

- Part qualification

- Prototype delivery

- Product delivery

Logistics

We welcome the opportunity to compete for your businessNetwork of 1300+ suppliers offer a competitive advantage

Rapid quote response

In-house low to medium volume assembly & prototype/model shop

Delivery

- Prototypes

- Subassemblies

- Machined Parts

- Sheet Metal

- Stampings

- Castings

- Weldments

- Cables & Harnesses

- Plastics

- Composites

Armorit will manage inventory and demand based on our customers’ needs. We offer a variety of delivery options ranging from drop shipments to line side delivery.

- Demand management

- Inventory management

- Warehousing

- Location control

- Consigned inventory

- Work-in-process

- Safety stock

- Management of spares

- Packaging

- Shipping plan

- Product delivery